Let’s go straight to the point. The reason there is no better time to install solar PV systems in your facilities or your homes, is the introduction of the NEM 3.0 program.

The Energy and Natural Resources Ministry (KeTSA) is introducing the Net Energy Metering (NEM) 3.0 program to provide an opportunity for more users to install the solar photovoltaic (PV) systems on the roofs of their respective buildings for electricity bill reduction. The NEM 3.0 will be in effect from 2021 to 2023 and the total quota allocation is up to 500 MW.

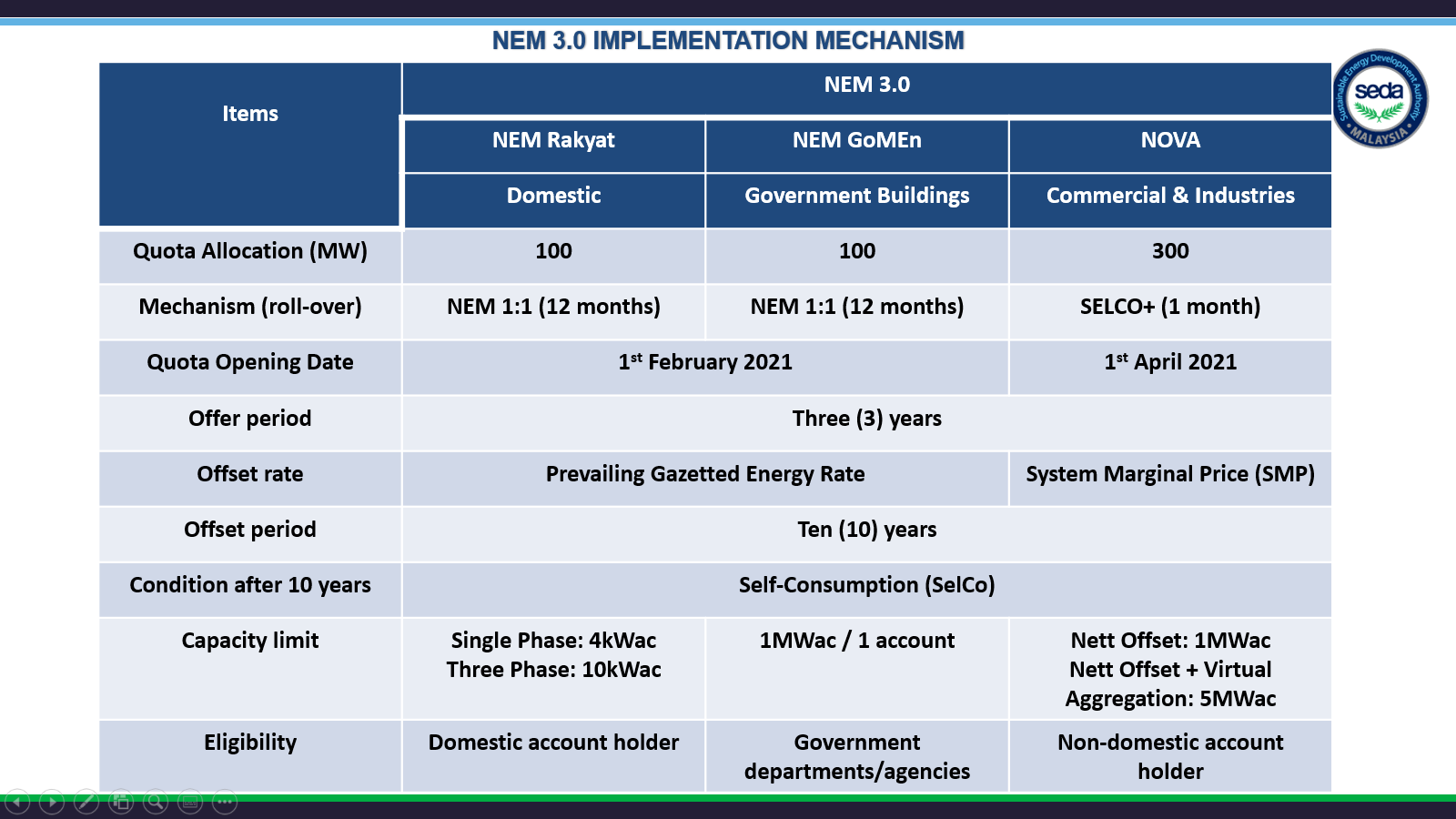

The NEM 3.0 program involves three initiatives

1. Program NEM Rakyat

Program NEM Rakyat will maintain the concept of “one-to-one” offset rate with a quota of 100 MW or until all quotas are exhausted and about 10,000 to 25,000 Tenaga Nasional Bhd (TNB) domestic account holders or between 40,000 and 100,000 households in the peninsula will enjoy electricity bill reduction.

Quota offered:

100MW

Implementation period:

1st February 2021 – 31st December 2023

2. Program NEM GoMEn (Government Ministries and Entities)

Program NEM GoMEn aims to reduce electricity bills in government buildings with a quota of 100 MW and about 100 government agencies in the peninsula will enjoy a reduction amounting to RM6 million per month.

Quota offered:

100MW

Implementation period:

1st February 2021 – 31st December 2023

3. Program NOVA (Net Offset Virtual Aggregation)

Program NOVA would help entrepreneurs, local companies and houses of worship to reduce electricity bills and the cost of doing business.

Quota offered:

300MW

Implementation period:

1st April 2021 – 31st December 2023

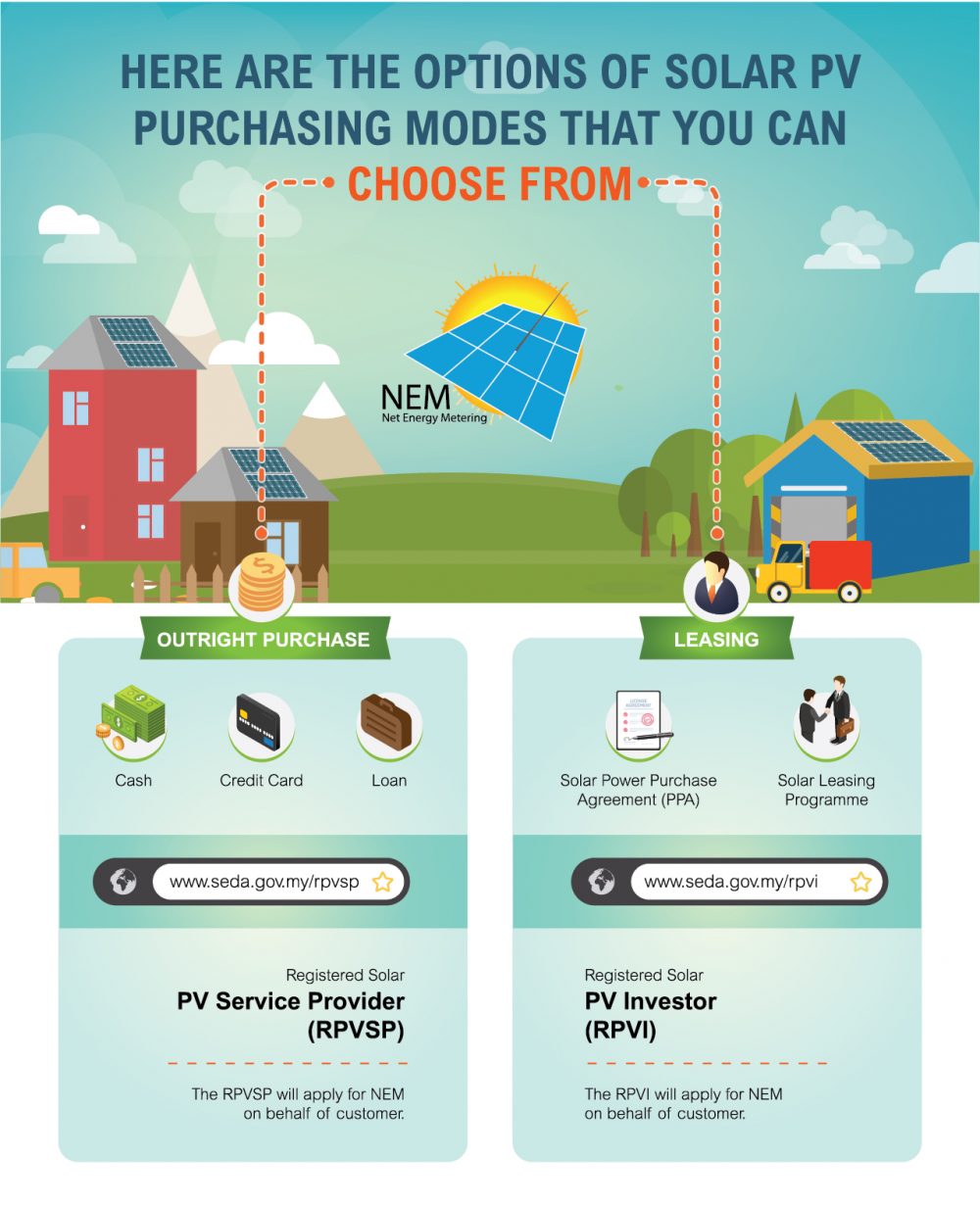

To learn on how you can take part in this NEM scheme, here are the options of solar PV purchasing modes that you can choose from:

We will be sharing more information on each program under NEM 3.0 so that you can take advantage of it’s benefits. Stay tuned!