Critical infrastructure’s top priority is to assure safety, health and welfare for all citizens.

According to the United States government’s Cybersecurity & Infrastructure Security Agency (CISA), critical infrastructure is the power used in homes, the water we drink, the transportation that moves us, the stores where we shop, and the Internet and communications we rely on to maintain our contact with friends, family, and colleagues.

With the Covid-19 pandemic, it has become undeniable that the communications industry is an integral component worldwide in terms of economy, public safety, businesses, and even interpersonal relationships.

There are many aspects needed to support and help the telecommunications industry achieve true resilience, and to protect infrastructures from various challenges. Here, we outline some of the most vital services which are often neglected.

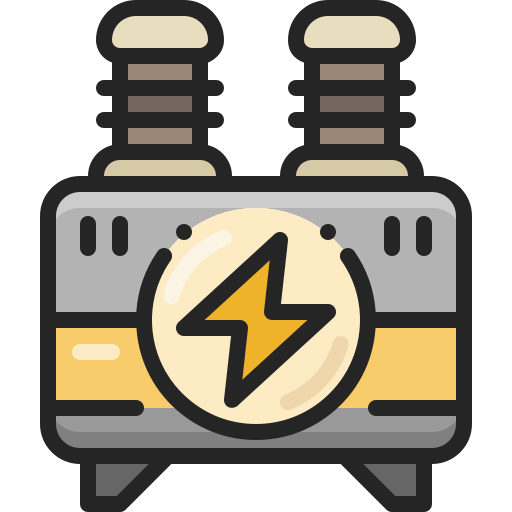

UPS system

Telecommunications companies, which must maintain the infrastructure in addition to data storage and backup, depend on uninterruptable power supply (UPS) systems. They ensure that the landline, internet and mobile communications function nationwide. Therefore the right UPS system is extremely important to maintain the network until a power failure has ended or an emergency generator takes over.

Very early warning aspirating smoke detection

Protecting these telecommuncations infrastructures against fires is vital but detecting the early signs of a fire can be a real challenge. Very-early-warning aspirating smoke detection can reveal the earliest signs of fire threats to help telecommunications operators potentially prevent disruption from fire that can put people, assets and data at risk.

Precision air conditioning

As telecom equipment generates large quantities of heat in small areas, six to ten times the heat density of normal office space, the air conditioning system must have more than just enough cooling capacity. It must have the precision to react quickly to a drastic change in heat load and prevent wide temperature fluctuations.

Conclusion

As 5G and the IoT move to center stage, telecommunications services provider have become key instruments to lead society in the new phase of the information era. At GreenBay, we provide these important services (and more) to assist telecommunications operators to provide the reliability of services that is expected from them.